Product Description

Agitator Directional Cogs Specifications

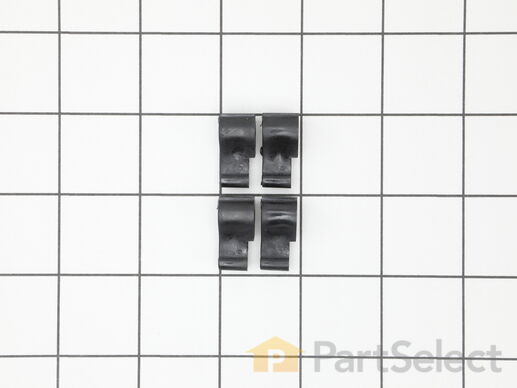

These agitator directional cogs are commonly referred to as dog ears. They come four to a package and are usually used with direct drive washing machines.

How Buying OEM Parts Can Save You Time and Money

Part Videos

Replacing your Whirlpool Washer Agitator Directional Cogs

Troubleshooting

This part fixes the following symptoms:

Will not agitate | Spins slowly | Spinning Issues | Marks left on clothes

This part works with the following products:

Washer, Washer Dryer Combo.

This part works with the following products:

Whirlpool, Kenmore, KitchenAid, Roper.

Part# 80040 replaces these:

AP3119063, 3109, 80040, 285612, 285770, 3366877, 387091, 80040, 80040VP, 99989668

Customer Reviews

Filter By Rating:

- < Prev

- 1

- 2

- 3

- Next >

Sort by:

Search filter:

Clear Filter

Your search term must have 3 or more characters.

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Sorry, we couldn't find any existing reviews that matched. Try using some different or simpler keywords.

Ray G - April 14, 2024

Verified Purchase

Right parts for the job

Great parts easy fast delivery

Lesa M - December 9, 2023

Verified Purchase

Wise choice

Done and fixed,saved $a service call would be overwhelming, been there done that. Simple fix.

Walter T - October 23, 2023

Verified Purchase

Parts were fine and were correct for the application

The parts came extremely late due to Canada Post shipping. Package was damaged but parts were ok. For the price of shipping this was annoying

Robert C - August 3, 2023

Verified Purchase

Easy repair.

The parts were exact replacement as needed.

Kenneth B - July 7, 2023

Verified Purchase

Worked as expected

Parts arrived in good time. Accurate description and easy to install. Installation video worked well to help me install this myself. Novice at repairing things, but even I was able to replace the broken parts and get the washer functioning properly. That said, it is probably an easy fix, but much cheaper than taking it to a repair shop.

Roland H - June 19, 2023

Verified Purchase

Did the trick

Took a bit searching until I found PartSelect who had the parts I needed to get my washing machine working again. Fairly simple repair. Thank you PartSelect for the parts and the video!

Geoff H - June 1, 2023

Verified Purchase

worked great. easy install

part came as expected. fit with my dishwasher. easy install

Marie-Lisane T - May 11, 2023

Verified Purchase

Easy!

Arrived quickly, installed in less than 15 minutes. Perfect!

Albert I - March 29, 2023

Verified Purchase

exactly what I wanted,Thank You.

very satisfied, Thank You.

Mario D - March 2, 2023

Verified Purchase

Easy repair

Easy repair, worked as expected.

- < Prev

- 1

- 2

- 3

- Next >

Customer Repair Stories

Average Repair Rating: 4.2 / 5.0, 276 reviews.

What's this?

- < Prev

- 1

- 2

- 3

- Next >

Sort by:

Search filter:

Clear Filter

Your search term must have 3 or more characters.

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Sorry, we couldn't find any existing installation instruction that matched.

washer wouldn't agitate

First pry off the cap of the agitator. Then using a socket remove the bolt that holds the plastic cup in place. Remove this cup by prying it loose from the two tabs that hold it in place. Once this cup is removed you can get to the broken cogs.

Slip the new cogs into the underside of the cup, and slide the cup back down in the agitator housing using the slots on the side for a guide. (You may want to remove the entire agitator and assemble everything upside down, then flip it all back over to mount, so the cogs don't fall out).

Tighten the bolt, snap the cap back in place on top of the agitator and your'e done. Easy repair.

Slip the new cogs into the underside of the cup, and slide the cup back down in the agitator housing using the slots on the side for a guide. (You may want to remove the entire agitator and assemble everything upside down, then flip it all back over to mount, so the cogs don't fall out).

Tighten the bolt, snap the cap back in place on top of the agitator and your'e done. Easy repair.

Other Parts Used:

-

mike from Kent, WA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set

931 of 1008 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer not agitating

On top of the agitator is a flat cap that is held in place by the friction of an o-ring, there are no fasteners. I would imagine one could get under the lip with a small screwdriver or butter knife to pop it off but I chose simply using my fingernails so as to not disfigure the cap. Under the cap you will find the head of the only bolt that holds the assembly together it is a 7/16 head and because it is in a 4" deep well your will need a 6" extension for your ratchet. Once the bolt is out the top of the agitator, the assembly with the cogs removes by hand. Set the assembly upside down on the counter, slide the black plastic ring off, pull the cogs out with your fingertips, install the new cogs put a new black ring on and set the assembly back in the agitator. Reinstall bolt. As the bolt is down in a tube, you cannot set it in place with your fingers and it will fall out of the socket. To hold the bolt in the socket during positioning you can either put a gob of Vaseline on the bolt head to hold it in the socket or form a small piece of paper over the bolt head and set it into the socket, the friction of the paper will hold the bolt into the socket. Took me less then 10 minutes, good luck

Other Parts Used:

-

Craig from Polk City, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Socket set

637 of 672 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

top half of agitator did not move during wash cycle

pull off softner dispenser, pop off agitator cap by inserting straight screw driver into small slot, remove bolt inside agitator with socket wrench and long extension, pull agitator straight up off shaft, place agitator on floor, with feet holding bottom half pull top half apart from bottom half by pulling straight up, note direction of old cogs remove and replace with new, reassemble

Other Parts Used:

-

dennis from new stanton, PA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Socket set

276 of 320 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Gearcase oil leak

To replace gearcase seals, first disconnect the power cord. Turn off water supply and remove water inlet hoses at washer (safety first). You may want to have a bucket available to catch water that will drain out of the hot/cold and drain hoses. Next, remove top agitator cap, seal and (7/16”) bolt (see diagrams on PartSelect). This will allow the top agitator and cogs to be removed. Grab the bottom agitator and rock it back and forth until it can be removed.

Suggestion: now is a good time to remove and clean the old soap and junk from drain holes in the top agitator and any junk that may be under the lower agitator.

Lay the washer on its right side. You will now have access to the motor, pump, hoses clutch and gearcase. Place a couple of 2X4X(5?) blocks under the tub to support it. Remove the electrical connector from the motor (this is clipped into place) and the two wires that go to the capacitor on the motor.(TIP: don’t put your finger across these terminals, SHOCK HAZARD) Remove the hose clamps and hoses, the two screws (5/16”) on each strap that holds the motor in place, you may have to use a screw driver to pop the straps off the motor. Remove the motor and pump by pushing the tub to the left and move the motor and pump to the right to clear the coupling. If you have not replaced the drive coupling, now would be a good time to order and replace. With the motor out of the way, remove the three (½”) bolts holding the gearcase to the chassis and pull to remove gearcase and shaft. If you are only replacing the drive shaft seal, you do not need to open the gearcase case. Stand the gearcase so the input shaft is facing up, or what fluid is left in the gearcase will come out. One question I see a lot is how do you remove the seal. One, buy a real expensive tool that you will only use once, or take a screwdriver with about a ¼” blade, stick it between the shaft and the seal, gently leverage the seal out while going around the shaft. After the seal is removed, oil can be added thru the seal hole. Understand that different oils are designed for different applications. That said, I used 90 weight gear oil from the local auto parts store, you can add it thru the seal hole. To install the seal, lightly tape it into the seal cavity, then use a socket that is close to the diameter of the seal and gently drive it in.

If you have to replace the top case seal, it will require you to take the gearcase apart. The advantage of this is, if you have an older washer, you can clean out the contaminated oil and sludge and check for wear on the parts, and replace as needed from PartSelect. Here’s a suggestion: if you have a digital camera, take pictures, this will really help when you put things back together.

Now look at the diagram that is provide by PartSelect, remove the clutch, remove the bolts on the top cover, try to keep it level or you may have a mess on your hands. Lift the cover up over the shaft. I found the top case seal very stubborn to remove. Using a small screwdriver, get between the case and the seal and gently pry it out. Replace the seal, again, by using a socket and gently taping into place. There is also a seal at the top of the drive gear that you may want to replace to keep the oil from going up into the clutch. Now its time to clean all of the years of gunk out of the case and gears. When you are ready, fill the bottom half of the gearcase with oil, about half a quart. To seal the case, I used a ultra blue silicone gasket sealer in a tube from my local auto parts store or sealant can be purchased from PartSelect. I used it on the top half of the gearcase case. Slide the top case over the shaft and evenly tighten the bolts. Reinstall the clutch to the gearcase shaft and install into the washer. I found that the motor bearings needed to be lubed, so I used white lithium grease in an aerosol can. Reinstall motor and don’t forget to put the electrical plug back into the motor and the wires that go to the capacitor and pump h

Suggestion: now is a good time to remove and clean the old soap and junk from drain holes in the top agitator and any junk that may be under the lower agitator.

Lay the washer on its right side. You will now have access to the motor, pump, hoses clutch and gearcase. Place a couple of 2X4X(5?) blocks under the tub to support it. Remove the electrical connector from the motor (this is clipped into place) and the two wires that go to the capacitor on the motor.(TIP: don’t put your finger across these terminals, SHOCK HAZARD) Remove the hose clamps and hoses, the two screws (5/16”) on each strap that holds the motor in place, you may have to use a screw driver to pop the straps off the motor. Remove the motor and pump by pushing the tub to the left and move the motor and pump to the right to clear the coupling. If you have not replaced the drive coupling, now would be a good time to order and replace. With the motor out of the way, remove the three (½”) bolts holding the gearcase to the chassis and pull to remove gearcase and shaft. If you are only replacing the drive shaft seal, you do not need to open the gearcase case. Stand the gearcase so the input shaft is facing up, or what fluid is left in the gearcase will come out. One question I see a lot is how do you remove the seal. One, buy a real expensive tool that you will only use once, or take a screwdriver with about a ¼” blade, stick it between the shaft and the seal, gently leverage the seal out while going around the shaft. After the seal is removed, oil can be added thru the seal hole. Understand that different oils are designed for different applications. That said, I used 90 weight gear oil from the local auto parts store, you can add it thru the seal hole. To install the seal, lightly tape it into the seal cavity, then use a socket that is close to the diameter of the seal and gently drive it in.

If you have to replace the top case seal, it will require you to take the gearcase apart. The advantage of this is, if you have an older washer, you can clean out the contaminated oil and sludge and check for wear on the parts, and replace as needed from PartSelect. Here’s a suggestion: if you have a digital camera, take pictures, this will really help when you put things back together.

Now look at the diagram that is provide by PartSelect, remove the clutch, remove the bolts on the top cover, try to keep it level or you may have a mess on your hands. Lift the cover up over the shaft. I found the top case seal very stubborn to remove. Using a small screwdriver, get between the case and the seal and gently pry it out. Replace the seal, again, by using a socket and gently taping into place. There is also a seal at the top of the drive gear that you may want to replace to keep the oil from going up into the clutch. Now its time to clean all of the years of gunk out of the case and gears. When you are ready, fill the bottom half of the gearcase with oil, about half a quart. To seal the case, I used a ultra blue silicone gasket sealer in a tube from my local auto parts store or sealant can be purchased from PartSelect. I used it on the top half of the gearcase case. Slide the top case over the shaft and evenly tighten the bolts. Reinstall the clutch to the gearcase shaft and install into the washer. I found that the motor bearings needed to be lubed, so I used white lithium grease in an aerosol can. Reinstall motor and don’t forget to put the electrical plug back into the motor and the wires that go to the capacitor and pump h

Other Parts Used:

-

Greg from Hemet, CA

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers, Socket set

148 of 162 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Agitator was not working

Step 1) Take off top cap with a flat head screw driver.

2) unscrew bolt (may need extension as it may be deep in the agitator.)

3) Take upper agitator off.

4) remove clog retainer and clogs.

5) insert new clogs and re-assemble.

total time 10 to 15 min.

2) unscrew bolt (may need extension as it may be deep in the agitator.)

3) Take upper agitator off.

4) remove clog retainer and clogs.

5) insert new clogs and re-assemble.

total time 10 to 15 min.

Other Parts Used:

-

Michael from Murray, KY

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers, Socket set

71 of 88 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Agitator would not spin

replaced the agitator cogs, bearing and the O-Ring. I looked all over Houston for these part, but found them on PartSelect. Had them in about 3 days. The repair only took about 30 minutes.

I saved a bunch of money!!

Thanks.

I saved a bunch of money!!

Thanks.

Other Parts Used:

-

Richard from Houston, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set, Wrench set

57 of 67 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

worn water pump and worn aggitator cogs

leaned and propped washing machine back to get access to pump, removed hose clamps and hoses,removed retainer clips, old pump was stuborn to remove but was able to pry off motor with screwdriver. sanded rust off metal shaft,put on new pump,replaced retainer clips, replaced hoses and clamps. set washer in upright position removed aggitator cap, used 7/16' socket with long extension,unscrewed bolt, pulled off aggitator sleave, removed cog unit, replaced cogs, put sleve back on and tightened bolt. I had the machine outside so I hooked up a water hose and an extension cord, put machine on small load and tested machine . worked like new. also when i finished the test I had noticed earlier that my hose screen had a mineral build up, cleaned that by lightly scraping and used little rust inhibitor that also tackles scales. total time was about 30 minutes. Wife is happy now and I was rewarded later.

Other Parts Used:

-

Chris from Morgan City, LA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers, Socket set

39 of 43 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

the agitator arm that rotates the clothes was not moving

pull up and off the fabric dispenser, remove the nut in the middle, and pull the piece off. underneath are 4 plastic things (dogs) that will just fall out. replace them (because they have little plastic things that jut out) and wear away. maneuver the piece back in place and tighten the screw back into place.

SAME JOB BY REPAIR CO. COST ME $95.00 THE FIRST TIME. WE USE HEAVY LOADS AND THE DOGS WEAR OUT AFTER A FEW YEARS. NOW I JUST CHANGE THEM MYSELF.***DID I ADD THAT I AM A WOMAN****

SAME JOB BY REPAIR CO. COST ME $95.00 THE FIRST TIME. WE USE HEAVY LOADS AND THE DOGS WEAR OUT AFTER A FEW YEARS. NOW I JUST CHANGE THEM MYSELF.***DID I ADD THAT I AM A WOMAN****

Other Parts Used:

-

Robin from Westwood, NJ

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Socket set

39 of 717 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Upper agitator stopped moving

First, I removed the softner cup from the top of the agitator. Second, I removed the plastic seal by pulling it out. I then used a socket to remove the bolt holding the agitator down. I then removed the agitiator from the machine and seperated the upper and lower agitator by placing my feet on the lower agitator and pulling up. The dog-ears were in the upper agitaotr section and easy to see and replace. I re-assembled in reverse order. The whole process took less than 30 minutes.

Other Parts Used:

-

Craig from Yadkinville, NC

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set

38 of 46 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Screw agitator would free spin

Job was easy! Just remove the top cap with a screw driver. With a socket and extension, remove the bolt that holds the agitator to the transmission shaft. Pull up on the agitator and lift it off the shaft. I had to use the screw driver to pry off the center piece that held the cogs because it did not what to separate from the rest of the agitator. Removed the pieces of the old, broken cogs, cleaned up the parts and installed the new cogs with the center piece upside down. I then took some silicone lubricant and lubed the area the cogs rub on and the opening the center piece spins in on the rest of the agitator. I then removed the Thrust Spacer on the mail part of the agitator but just lifting off the old one and putting on the new one. Then, with the center piece that holds the cogs upside down I inserted it into the upper corkscrew section of the agitator so that the cogs would not fall out. While holding the two pieces together, I turned it back right-side-up and installed it back onto the other part of the agitator and then on the shaft. Re-installed the bolt and tightened with the socket. That's it! It sounds more complicated then it really was.

Other Parts Used:

-

Charles from San Diego, CA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set

37 of 42 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

- < Prev

- 1

- 2

- 3

- Next >

Questions and Answers

Ask our experts a question about this part and we'll get back to you as soon as possible!

- < Prev

- 1

- 2

- 3

- Next >

Sort by:

Search filter:

Clear Filter

Your search term must have 3 or more characters.

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Sorry, we couldn't find any existing answers that matched.Try using some different or simpler keywords, or submit your new question by using the "Ask a Question" button above!

Parker

July 20, 2017

We have figured out that we need to replace the agitator dogs in our washer. We aren’t that handy but we also don’t have the funds to get a repair person to do it. Especially if its an easy job. Do you think this is something I could do myself with a little DIY experience? How hard is this project (roughly)?

Hello Parker, to make this repair you will need to remove the center bolt in the agitator, and then lift the agitator out. You will need to separate the upper part from the lower with applied force. Once these are separated, if you tip the upper part of the agitator over, the dogs will fall right out. You should have no trouble replacing the agitator dogs 80040. Best of luck with this repair.

111 people found this helpful.

Was this helpful?

Thank you for voting!

Conor

July 20, 2017

I was told to replace my agitator dogs and that it would help fix the agitating problem. Everything seems to be in good condition but it still isn’t agitating and also it looks like the bolt is falling out. What should I do

Hi Connor, we recommend administering some Loctite to the bolt to keep it in place. To diagnose the agitating problem, you need to pull the agitator out and see if the shaft is rotating to move the agitator. If not then it is a problem with the gearcase. If it is then the agitator is the problem. I hope this helps!

39 people found this helpful.

Was this helpful?

Thank you for voting!

Chris

November 12, 2017

The top of the agitator seems to be hardly moving. From reading the trouble shooting from other customers it seem to be the directional cogs are bad. Which i’ll be ordering and changing. I feel like the lower agitator is not moving a whole lot. The washer seems to be spinning and draining fine with no alarming noise.( i did a load of laundry and lifted the lid enough to see so i can see it work before i pulled it apart to inspect) i removed the agitator and the cogs look worn. I inspected the rest of the agitator and no signs of being cracked or stripped. Could that be the way the machine agitatates? I was wondering if there was something else i should replace? Thanks for you time.

For model number LSQ9030PQ5

Hi Chris,

Thank you for your question. In a situation where the washing machine is not agitating, the directional cogs fix the issue the majority of the time. There are some other parts that you will need to check to see which one is causing the issue. You will also need to check the direct drive motor coupling, the agitator cam kit, the inner seal cap, the thrust spacer, the lid switch, the clutch assembly and the gearcase. I hope this helps. Thank you and have a great day!

31 people found this helpful.

Was this helpful?

Thank you for voting!

CHERYL

January 26, 2018

Is the top part of the agitator (the spiral part below the fabric softener dispenser) supposed to move during operation? We fixed our machine where it would continue operating when we opened the door and that part of the agitator is not moving. The bottom part agitates back and forth but the top spiral part does not move and the clothes don't go down into the water without us pushing them down. Also there is a noise when operating.I

For model number WTW5540SQO

Hello Cheryl, Thank you for your inquiry. Yes the upper part of the agitator is supposed to agitate as well, if it is not you may want the check the directional cogs, the thrust spacer, and the agitator cam kit to see if any of the pieces are cracked or broken. Hope this helps!

25 people found this helpful.

Was this helpful?

Thank you for voting!

Pat

February 7, 2018

How do you separate the upper half of agitator from lower on my model washer lsq9010pw3

For model number LSQ9010PW3

Hello Pat, thank you for your question. Here is some instructions from another customer that might help you!

First I removed the liquid fabric softener cover, then removed the seal with my fingers, then used a socket with an extension to remove the single bolt that holds the agitator to the spindle.

Next, I pulled up to remove the agitator and tipped it upside down to take out the centrifugal mechanism. Then, I simply replaced the old parts with the new ones, and put it back together, as it shows in the included diagram. It took about fifteen minutes.

I hope this helps!

25 people found this helpful.

Was this helpful?

Thank you for voting!

Victoria

July 20, 2017

What does this purchase come with? How many come with it and how many do I need?

Hi Victoria, this pack comes with a set of 4 and you should only need to purchase one package. Please let me know if you have any further questions.

22 people found this helpful.

Was this helpful?

Thank you for voting!

Vince

November 18, 2017

The agitator will not come apart. I took the screw out and lifted the whole agitator out and I cannot get them apart. I have to put in new dog ears. Any help on getting them apart?

For model number lsq9549lw0

Hello Vince,

Thanks for your question. You can separate the agitator into its two pieces. Stand on the lower half of the agitator and pull on the upper half to separate it. Dump the upper half upside down to remove the

cam set and agitator bolt. With the cam assembly out, you remove the retainer bearing to access the dog ears. Put the bearing away and dump the dogs off the cam.

To install the new ones, align the dog ears with the curve of the cam properly and press them in. Put the retainer bearing back on, put the assembly back in the agitator - drop it through the hole of the agitator. Put the two sections of the agitator back together using the locking tabs aligned with the cam.

Put the upper agitator onto the lower agitator, put your hand inside, and lock the two pieces together. With the agitator assembled again, put it back in the washer. Use the agitator bolt and guide it back into the hole with your 7/16" socket. Put the dust cap back in as well (use liquid detergent to make it easy), and then replace the dispenser.

19 people found this helpful.

Was this helpful?

Thank you for voting!

Carla

August 22, 2017

Everything works but will not spin. Tap the gray box on bottom in back and it works. So what part do i need?

For model number WTW4800XQ4

Hi Carla,

Thank you for your inquiry. Where the washer is not spinning, the parts you will need to check are the agitator directional cogs, the agitator cam kit, the shift actuator, the lid latch assembly, the drive belt, the inner cap seal, the drive block, the clutch assembly, the agitator and the upper agitator, the agitator cap barrier with seal and thrust spacer. I hope this helps. Thank you and have a great day!

18 people found this helpful.

Was this helpful?

Thank you for voting!

John

February 27, 2018

My washer washes properly and the water drains out properly but sometimes does not spin either after the wash or after the rinse. Any suggestions?

For model number LSQ9549W0

Hello John, thank you for your question. If the unit is draining but not spinning, there are a few parts you will want to check first. The Lid Switch PartSelect Number: WP8054980, the Direct Drive Motor

Coupling Part Number: 285753A and the Clutch Assembly Part Number: 285785. I hope this helps!

16 people found this helpful.

Was this helpful?

Thank you for voting!

Chanta

August 14, 2017

My washer will wash fine but it will not spin, it's just buzzing when time to spin, the water will pump out.

For model number ETW4400WQ0

Hello Chanta, thank you for contacting us. The most common fix for this issue based on your model would be the direct drive motor coupling, part number PS1485646 Hope this helps!

14 people found this helpful.

Was this helpful?

Thank you for voting!

- < Prev

- 1

- 2

- 3

- Next >

✖

Ask a Question

Ask our experts a question on this part and we'll respond as soon as we can.

Sorry, we couldn't find a match for "".

Here's a guide for finding your model number.

Something went wrong. Please try again later.

Your Question Has Been Submitted!

Our experts will send you an email as soon as your question has been answered.

Related Parts

Model Cross Reference

This part works with the following models:

PartSelect Number: PS388034

Manufacturer Part Number: 80040

Manufacturer Part Number: 80040

Brand

Model Number

Description

Kenmore

10682872600

Washer

- Kenmore Washing Machine Model 106.82872600 (10682872600, 106 82872600) Parts