Product Description

Direct Drive Motor Coupling Specifications

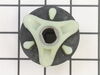

This coupling kit is located between the motor and the transmission on direct drive washers with no belt. This is the newer version and is made with new metal sleeves for added strength.

How Buying OEM Parts Can Save You Time and Money

Part Videos

Replacing your Whirlpool Washer Direct Drive Motor Coupling

Troubleshooting

This part fixes the following symptoms:

Will not agitate | Spins slowly | Will not drain | Burning smell

This part works with the following products:

Washer, Washer Dryer Combo.

This part works with the following products:

Whirlpool, Kenmore, KitchenAid, Roper.

Part# 285753A replaces these:

AP3963893, 1195967, 285753A, 20103869, 21003, 280152, 285140, 285743, 285753, 285753A, 285753AVP, 3352470, 3363664, 3364002, 3364003, 62672, 62693, 661560, 80008, 8559748

Customer Reviews

Filter By Rating:

- < Prev

- 1

- 2

- 3

- Next >

Sort by:

Search filter:

Clear Filter

Your search term must have 3 or more characters.

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Sorry, we couldn't find any existing reviews that matched. Try using some different or simpler keywords.

Ryker M - May 2, 2024

Verified Purchase

Simple fix, good instructions

Easy install of part, helpful videos and reviews made fixing our washing machine a breeze. Very satisfied with the quick delivery and customer care throughout the entire process!

Adam W - May 22, 2023

Verified Purchase

Easy repair, back up and running

Easy to order, part came fast and was easy to install. Machine is back up and running.

Darry M - March 30, 2023

Verified Purchase

Great supplier

With the help of utube and partselect , washer is working again. The part supplied was updated and stonger. Should last forever.

Michael Z - March 2, 2023

Verified Purchase

Easy Fix

Part shipped fast, as described, and worked great.

Christiane B - January 6, 2023

Verified Purchase

Perfect! Easy to install and my washer works like new!

Exactly what I needed to fix my washer. So glad I didn't have to purchase a new one. If I ever need parts again, I'm definitely coming here!

David S - May 26, 2022

Verified Purchase

Great part work as expected

The part came within 48 hours, great service and the washer was easily repaired. thank you

Sandy B - November 3, 2021

Verified Purchase

Part better that OEM

Part looked better than OEM, due the this on had steel which contacted the shafts original was all nylon.

Jack E - October 27, 2021

Verified Purchase

Washer part

No issues. Website nailed the problem. New part uses metal insert n the plastic where the old one was stripped so should last longer.

Reg S - August 18, 2021

Verified Purchase

Worked!

Totally satisfied with order processing and fit of the parts. You should be a dedicated DIY type person but not a hard job to complete in under one hour.___ My only problem was Purolator put the shipment at the wrong address. They even showed this on their tracking status. Fortunately, due to this, I was able to go and retrieve items myself with no added delay.

John V - August 9, 2021

Verified Purchase

ordered without looking, but old one still good

BUT, I'm keeping it, just in case.

- < Prev

- 1

- 2

- 3

- Next >

Customer Repair Stories

Average Repair Rating: 3.2 / 5.0, 251 reviews.

What's this?

- < Prev

- 1

- 2

- 3

- Next >

Sort by:

Search filter:

Clear Filter

Your search term must have 3 or more characters.

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Sorry, we couldn't find any existing installation instruction that matched.

No movement from Basket & agitator

The job looked intimidating but turned out to be very easy.

First take off the water pump by removing the two clips that hold it in place. Place a shallow pan under the pump to catch the water that is in the pump and hoses. Open the hose clamps with a pair of pliers or channel locks (better) and slide the hoses off of the water pump.

The motor comes off next. Unplug the electrical connector from the motor and two wires from the capacitor. Remove the two screws holding the clamps in place and then pop off the two clamps. You will need to hold up the motor with one hand while you remove the clamps or it will fall to the floor once the clamps are removed.

One piece of the coupling assemble will be attached to the motor and the other will be attached to the gearcase drive shaft. If you want to clean up the mess created by the shredded rubber center piece of the coupling assembly you will have to take off the motor mounting plate. It is held on by two bolts and removing it makes installing the coupling easier but probably not necessary.

Push the back half of the coupling on to the gearcase drive shaft until the shaft is flush with the face of the coupling. Install the new rubber center piece on to the coupling then re-install the motor mounting plate. Install the other half of the coupling on to the motor shaft and lift the motor up to the coupling. You have to rotate the motor shaft by spinning the fan blades until the coupling lines up so you can slide it into the other half of the coupling. Then just reattach the motor, connectors and water pump in the reverse order of disassembly.

First take off the water pump by removing the two clips that hold it in place. Place a shallow pan under the pump to catch the water that is in the pump and hoses. Open the hose clamps with a pair of pliers or channel locks (better) and slide the hoses off of the water pump.

The motor comes off next. Unplug the electrical connector from the motor and two wires from the capacitor. Remove the two screws holding the clamps in place and then pop off the two clamps. You will need to hold up the motor with one hand while you remove the clamps or it will fall to the floor once the clamps are removed.

One piece of the coupling assemble will be attached to the motor and the other will be attached to the gearcase drive shaft. If you want to clean up the mess created by the shredded rubber center piece of the coupling assembly you will have to take off the motor mounting plate. It is held on by two bolts and removing it makes installing the coupling easier but probably not necessary.

Push the back half of the coupling on to the gearcase drive shaft until the shaft is flush with the face of the coupling. Install the new rubber center piece on to the coupling then re-install the motor mounting plate. Install the other half of the coupling on to the motor shaft and lift the motor up to the coupling. You have to rotate the motor shaft by spinning the fan blades until the coupling lines up so you can slide it into the other half of the coupling. Then just reattach the motor, connectors and water pump in the reverse order of disassembly.

Other Parts Used:

-

Jeff from Wayne, NJ

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Socket set

1091 of 1172 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer made a loud banging noise at end of spin cycle, leaked water and agitator seemed loose

After entering the model number of your appliance you will be taken to a page where all of the parts are displayed by sections. On that page about in the middle there is a heading called "Find Part By Symptom." I figured out from there which symptom the washer had and read what other people were saying and how they made the repairs. Basically I had three problem areas, Noise, Leaking and a problem with the agitator. I focused on the loud noise first and decided I needed to replace the clutch/brake assemblies. I found the clutch parts page and on that page there was a video on how to make this repair. This video is all you need to gain access to all moving parts located under the cabinet. Which ever part you are replacing, I recommend watching this video! After removing the console, back panel and cabinet then laying the machine on its back just as seen on the video, I had access to the water pump, motor, transmission and related clutch/brake parts. As it turned out I did not need the clutch/brake assembly but as a precaution and because the parts were cheap, I replaced the motor coupling, water pump and tub wear pads. I decided to replace the agitator assembly because of several worn parts associated with the dog ears/drive shaft ETC. I put the machine back upright and took off the top cap on the agitator, then there is an inner cap with seal that gives access to the 7/16" bolt you must remove to remove the agitator. However once the agitator was removed I noticed metal shavings and play in the shaft. I used a spanner wrench to remove the spanner nut. I removed the Plastic Tub Ring (has several clips around the outer tub), then removed the inner washer tub to replace the Drive Block. Replacing the Drive Block stopped the loud noise at the end of the spin cycle. Now just reverse the order to put the machine back together and your done. For my situation it was best to take the machine apart and decide which parts I needed before ordering to minimize errors. These machines are made very cheaply and are designed to brake at some point in time and it is very easy to determine which parts are worn because most are made of plastic. In this process I also noticed where my leaks (did I say Leaks) were coming from. There were two hose clamps installed improperly from the factory, so check all clamps, hoses ETC. and you should be good to go.

Other Parts Used:

-

Dexter from Milwaukie, OR

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set

485 of 570 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Broken Coupling

Very easy -

1. Removed hoses from the pump

2. Removed Wiring harness from the motor

3. Unscrewed saftey screws from both clamps which hold the motor against the motor bracket.

4. Using a screw driver I easily removed/pryed the clamps from the motor.

5. I then removed the broken plastic coupler from the motor shaft and installed the new one coupler.

6. I did the same thing on the clutch side.

7. I set the Rubber coupler in clutch side.

8. Put motor back on until couplers joined together.

9. Placed Brackets back on Motor (patience here).

10. screwed back saftey screws on clamps.

11. connected hoses back.

Thats it... 45 minutes at most .. Save me from having to buy a new easher. I was convinced I was going to have too until I peeked underneatch the washer and saw the rubber coupler on the ground...

1. Removed hoses from the pump

2. Removed Wiring harness from the motor

3. Unscrewed saftey screws from both clamps which hold the motor against the motor bracket.

4. Using a screw driver I easily removed/pryed the clamps from the motor.

5. I then removed the broken plastic coupler from the motor shaft and installed the new one coupler.

6. I did the same thing on the clutch side.

7. I set the Rubber coupler in clutch side.

8. Put motor back on until couplers joined together.

9. Placed Brackets back on Motor (patience here).

10. screwed back saftey screws on clamps.

11. connected hoses back.

Thats it... 45 minutes at most .. Save me from having to buy a new easher. I was convinced I was going to have too until I peeked underneatch the washer and saw the rubber coupler on the ground...

Other Parts Used:

-

Hugo from Frisco, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Socket set

217 of 230 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Would not spin unless helped

Turned off water supply, disconnected hoses so I could lay on its back.( drain hose also ) have something to catch all the water in. There will be some residual water so have something to wipe it up. Removed agitater, then I removed the spanner nut with hammer and punch. layed it on its back, removed the three mounting bolts that hold the gearcase to the tub support. Removed wire harness and ground wire , pulled gearcase and shaft out . Removed spin tube thrust washer, removed support ring from groove in shaft , removed retaining ring , slid clutch off shaft ,installed new clutch. Take care to watch how parts are removed so that they are installed in proper orientation. Since I had it this far apart I decided I should replace the coupling. I removed the two motor retainers , seperated coupling , pulled both halves off shafts , installed new halves , they go on a lttle tight , newer couplings have metal inserts , aligned coupling halves , inserted together , put motor retainers back on , tightened small screws,done.

Other Parts Used:

-

Ernest from Oakdale, CT

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Socket set

114 of 136 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Tub wouldn't turn, but motor would allow it to drain.

I took the two screws for the control panel out and tilted it up and back. Then remove the two metal clips which held the outer panel to the back panel. After disconnecting the power and water I tipped the washer on its back. I had to remove two clips to take the water pump off of the motor, then removed the two screws and clips which held in the motor. After removing the motor, I found the coupler was bad. To remove the gearcase, I took out the softener dispenser and removed one bolt to take out the agitator. Under the agitator was a clip. Three bolts held the gearcase to the frame. After removing them, the gearcase pulled straight out the bottom. Replacement was just a reverse process, with the addition of a light coat of grease to the gearcase shaft.

Other Parts Used:

-

Troy from Storm Lake, IA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set

107 of 135 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

would not completely spin all the water out of clothes

I replaced the clutch and coupler. The clutch was well worn. My wife had washed three or four loads of heavy rugs and we think that was the cause of the premature wear. We now take the rugs to a commercial laundry. The coupler was OK but the new coupler has metal instead of plastic inserts so I decided to replace it while I had it torn apart. The machine is now running like it was new.

0.Disconnect supply hoses and electrical. Refer to the parts breakdown pictures on the PartSelect website. I refer to only the numbers so you may have to match the part to a particular diagram.

1. Remove the agitator by pulling up on the fabric softener dispenser #1. Clean out the excess liquid and "residual gunk". Grab one off the tabs of the plastic cap #23 and pull gently. The plastic cap (~ 3" in dia) is held in place by a rubber O-ring #24. The cap comes out easily exposing the bolt that holds the agitator to the drive shaft. Remove the bolt. and the agitator comes right out.

2. Turn the machine over on its front. You do not need to remove the back panel.

3. Get plenty of rags to soak up the water before you remove the hoses from the water pump #22 on the end of the motor. A quart or more remains in the pump and hoses. Remove the two hoses.

4. Disconnect the wiring harness from the motor#29. There is a small plastic "catch" on the bottom of the connector that must be lifted to remove the connector. It's kind of hard to see but it's there and it's part of the connector.

5. Remove the three bolts #10 that hold the gearcase #9 to the bottom of the tub assembly.

6. Remove the gearcase, the drive shaft, the motor, and the water pump as one unit. You will need to lift them a little to get clearance because the tub has settled down. Just lift the tub and all and pull the assembly out. Get them out to a spot where you have room to work on them. The water pump may still have bit of water.

7. Replacing the clutch. Remove the clutch parts from the bag and lay them out where you can see everything. Refer to the instructions in the bag to select the correct spring and to see how the keeper spring is installed. Remove the washer, keeper ring, and clutch assembly, and plastic clip#15 remembering the order and the orientation. Install the new clutch in reverse order.

8. You will have one plastic part #15 left over. It goes on the bottom of the tub after you remove a key ring.

9. Replacing the coupler. note the orientation of the water pump#22 and remove it by removing the two retainers #21. set it aside.

10. Remove the screws#23 and retainer clips#17. Separate the motor#20 from the gearcase#9 to expose the coupler. Replace the coupler, reattach the motor to the gearcase, and the water pump to the motor.

11. The reassembly is pretty much a reverse of the assembly.

0.Disconnect supply hoses and electrical. Refer to the parts breakdown pictures on the PartSelect website. I refer to only the numbers so you may have to match the part to a particular diagram.

1. Remove the agitator by pulling up on the fabric softener dispenser #1. Clean out the excess liquid and "residual gunk". Grab one off the tabs of the plastic cap #23 and pull gently. The plastic cap (~ 3" in dia) is held in place by a rubber O-ring #24. The cap comes out easily exposing the bolt that holds the agitator to the drive shaft. Remove the bolt. and the agitator comes right out.

2. Turn the machine over on its front. You do not need to remove the back panel.

3. Get plenty of rags to soak up the water before you remove the hoses from the water pump #22 on the end of the motor. A quart or more remains in the pump and hoses. Remove the two hoses.

4. Disconnect the wiring harness from the motor#29. There is a small plastic "catch" on the bottom of the connector that must be lifted to remove the connector. It's kind of hard to see but it's there and it's part of the connector.

5. Remove the three bolts #10 that hold the gearcase #9 to the bottom of the tub assembly.

6. Remove the gearcase, the drive shaft, the motor, and the water pump as one unit. You will need to lift them a little to get clearance because the tub has settled down. Just lift the tub and all and pull the assembly out. Get them out to a spot where you have room to work on them. The water pump may still have bit of water.

7. Replacing the clutch. Remove the clutch parts from the bag and lay them out where you can see everything. Refer to the instructions in the bag to select the correct spring and to see how the keeper spring is installed. Remove the washer, keeper ring, and clutch assembly, and plastic clip#15 remembering the order and the orientation. Install the new clutch in reverse order.

8. You will have one plastic part #15 left over. It goes on the bottom of the tub after you remove a key ring.

9. Replacing the coupler. note the orientation of the water pump#22 and remove it by removing the two retainers #21. set it aside.

10. Remove the screws#23 and retainer clips#17. Separate the motor#20 from the gearcase#9 to expose the coupler. Replace the coupler, reattach the motor to the gearcase, and the water pump to the motor.

11. The reassembly is pretty much a reverse of the assembly.

Other Parts Used:

-

Ron from bellbrook, OH

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set

98 of 108 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The motor turned with loud noise ,but nothing else worked

I used "Emley's Cheap and Easy Repair" book to remove,install and reassemble the machine.

A lot of time was used to clean the filthy tub and basket.

While replacing the broken motor coupling I decided to replace some of the seals.

PartSelect got the ordered parts to me in a couple of days.

I wouldn't hesitate to do the job again.

A lot of time was used to clean the filthy tub and basket.

While replacing the broken motor coupling I decided to replace some of the seals.

PartSelect got the ordered parts to me in a couple of days.

I wouldn't hesitate to do the job again.

Other Parts Used:

-

Bob from East Palestine, OH

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set, Wrench set

81 of 174 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Wouldn't agitate or spin.

First, I removed two screws holding the bottom fiberboard panel in place, and the panel, to gain access to the motor, transmission, and pump. Unfortunately, I had the machine tilted to the front, and didn't have room to release the pump. I had to set the machine back up, and get manuvered around so I could lay it on it's back (I was working in the confines of a small laundry room). Once on it's back, I released the two clips holding the pump with a flat head screwdriver, lifted it up and out of the way without having to disconnect any of the piping, then I released the two clips holding the motor, again with a flathead screwdriver, disconnected the wiring plugs, and capacitor wires, then lifted the motor up and out of the machine. I then removed the two bolts holding the motor mounting plate to the transmission. Then, again using a large flat head screwdriver, I pried the transmission coupling half off the transmission shaft, I had to work it up, while turning the shaft, and then the same for the motor half. I then wiped off both shafts, and gently tapped both coupling halves back onto the shafts,

( this is easier using a socket that is just large enough to go over the shafts). Then I reinstalled the motor mounting plate, slipped the rubber coupling onto the transmission coupling half, lifted the motor into place, and rotated from the pump end to line up with the remaining holes on the rubber coupling. I then reinstalled the clips used to hold the motor in place, reinstallation only took thumb pressure to snap back into place, then, I reinstalled the pump, using the same method, and reconnected the wiring plugs and copacitor leads. Lastly, I reinstalled the fiberboard panel into the bottom, and set the machine upright, slid back into place, and reconnected the hoses and electrical, and tested the machine. Worked perfectly.

In actually took longer to disconnect the machine, and get it out and back in, than it did to replace the coupling.

( this is easier using a socket that is just large enough to go over the shafts). Then I reinstalled the motor mounting plate, slipped the rubber coupling onto the transmission coupling half, lifted the motor into place, and rotated from the pump end to line up with the remaining holes on the rubber coupling. I then reinstalled the clips used to hold the motor in place, reinstallation only took thumb pressure to snap back into place, then, I reinstalled the pump, using the same method, and reconnected the wiring plugs and copacitor leads. Lastly, I reinstalled the fiberboard panel into the bottom, and set the machine upright, slid back into place, and reconnected the hoses and electrical, and tested the machine. Worked perfectly.

In actually took longer to disconnect the machine, and get it out and back in, than it did to replace the coupling.

Other Parts Used:

-

Roger from Swainsboro, GA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set

79 of 88 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer would drain, agitate but not spin and was very noisy and would vibrate heavily

I first watched the youTube vidio on yhe PartSelect web site. After getting a visual of the repair, I decided to tackle the job with a better understanding and knew the repair was easy to purform. First I took the two screws out of the contrl panel on top of the washer, rolled the panel back to expose the clips that hold the metal cabinet to the back panel of the washer. After removing the cabinet I was ready to lay the washer on it's back and had a clear view of the pump, motor and clutch... I was able to easly identify these parts because I took time to watch the video. Using a flat head screwdriver I removed the clips that hold the pump to the motor... Without disconnecting the hoses connected to the pump I pushed the pump to the side and out of the way. This further exposed the motor. Using the flat head screwdriver, I removed the clips holding the motor to the transmission (they just snap off like they did on the pump). The motor was now ready to be removed from the transmission ( it just lifts off) before removing it I disconnected the power suply wire from the motor... Now the motor can be completely removed. I identified the drive couupler 1/2 was on the motor shaft the other 1/2 was on the transmission shaft.. On both halfs the splines were broken. I removed the old broken drive coupler. Since I already had the machine so far apart i figured i would replace the clutch also. Using a deep socket ratchet wit an extention I removed the agator... I then unbolted the transmission (only three bolts) I gentely pulled the transmission and shaft out of the bottom of the washer. This exposed the clutc assembly, I removed the clutc ( which wasn't bad or wore by the way) and replaced it.... I figured I had it and I was this far into the repair why not. After relpasingvthe clutch, I slid the shaft and transmission back into place tightened the bolts and that was done. I then slid/replaced the drive coupler... Placing one half on the motor shaft the other on the transmission shaft, placed the rubber bushing on the oneside of the plastic drive coupler. And mounted the motor back on the transmission utilizing the clips I took off earlier. Once the motor was in place I installed the waterpump fastened by the clips. Flipped yhe washer up, replaced the cabinet... Tightened down the the control panel and was ready to do some wash..: the washer runs perfect now and I saved myself about $700.00. It was allot easier than I thought it would be... Watching the youTube video is the secret to success. The washer is running like the day I bought it new... All for only 53.00. Hats off to everyone at PartsSelect for going above and beyond. Regards, ~ Michael

Other Parts Used:

-

Michael from Schuylkill Haen, PA

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers, Socket set

59 of 63 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer would not spin

took off back and sides to the washer. laid the washer on it's back and removed worn and broken parts. replaced these parts and put everything back together. The top part of the agitator hasn't worked in a while, while we had it apart we also replaced the clogs. The washer works better than it has in a long time. Spins a lot more water from the clothes which makes drying faster. I would surely do this again. A lot cheaper than a new washer.

Other Parts Used:

-

Mary from Madisonville, KY

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Socket set, Wrench set

58 of 1327 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

- < Prev

- 1

- 2

- 3

- Next >

Questions and Answers

Ask our experts a question about this part and we'll get back to you as soon as possible!

- < Prev

- 1

- 2

- 3

- Next >

Sort by:

Search filter:

Clear Filter

Your search term must have 3 or more characters.

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Sorry, we couldn't find any existing answers that matched.Try using some different or simpler keywords, or submit your new question by using the "Ask a Question" button above!

Maddie

July 20, 2017

When I’m using my washer it is no longer spinning but it is making sounds like it is, and it is still draining normally, what should I do?

Hello Maddie, we recommend that you inspect the motor coupling first. If the motor coupling is faulty, the tub will not spin properly. Please let us know if you have any further questions.

126 people found this helpful.

Was this helpful?

Thank you for voting!

April

August 28, 2017

My washer fills up normal but will not agitate and makes a sound like a drill also will not drain.

For model number RAB5232EW1

Hello April, thank you for contacting us. It does sound like the direct drive coupling has given out. This direct drive motor coupling, also known as a coupling kit, is a newer version of the part and is used in your washer. The piece includes new metal sleeves that have been added in order to strengthen the part. Hope this helps!

44 people found this helpful.

Was this helpful?

Thank you for voting!

Cleve

July 20, 2017

The basket and the agitator were not working and I diagnosed that I needed to replace the motor coupling. That was a while ago. Now it stopped spinning and the motor coupling seems to still be in good condition, what else should I be looking for?

Hi Cleve, it sounds like you may have a problem with your lid switch. Try closing the lid of your washer, if you hear a clicking sound that is a good indicator that it is working. If you do not hear a clicking sound you most likely need to replace the lid switch. We also recommend checking the lid switch wiring harness connection, as it might have come loose during your motor coupling repair. I hope this helps.

21 people found this helpful.

Was this helpful?

Thank you for voting!

Ronnie

July 20, 2017

My washing machine is acting up and i think it could be the motor coupling or the agitator but would like to confirm. It is spinning during the wash cycle but during the spin cycle it isnt. The basket is spinning good but I think the agitator stopped spinning. Also not sure if it is relevant but the washer seems to be draining normally.

Hi Ronnie, unfortunately it sounds like the transmission is bad and needs replacing. This is the transmission you would need for your model 3360629, best of luck with this repair.

18 people found this helpful.

Was this helpful?

Thank you for voting!

Jason

August 10, 2017

After wash cycle it starts to spin but not drain the water out. I already replaced the direct drive pump.

For model number GSX9885JQ0

Hi Jason,

There is one other part that might be causing your appliance not to drain. The Lid Switch Assembly. If that part fails your appliance will not drain. However you should also check all of your hoses to make sure that nothing is blocking them. That will also not allow your appliance to start to drain. Good luck with your repair!

12 people found this helpful.

Was this helpful?

Thank you for voting!

Stefan

August 27, 2017

Washer makes a loud banging noise at end of spin cycle until the tub stops spinning

For model number WTW57ESVW1

Hi Stefan,

Thank you for the question. Sounds like you need to replace the Center post Bearing and Seal Assembly. This can cause a banging or rubbing noise. I also recommend replacing the Direct Drive Motor Coupling. Both parts are knob to make noise when they wear out and when replacing one of the parts it is recommends to replace both.

Hope this helps!

11 people found this helpful.

Was this helpful?

Thank you for voting!

Related Parts:

Alana

August 12, 2017

I changed the the agitator dogs and whole kit but washer still barely agitates and agitator turns easily both ways. Do i need the replace the motor couplings or get a new washer? Repairman wants to charge me $200 to come look at it. There is no belt that i can see. Please help i am a single woman on a tight budget , but very handy your videos have helped me repair dryer already.

For model number ITW4300SQ3

Hi Alana,

Thank you for your inquiry. Some other parts that may fix the issue are the agitator, the agitator coupler and cap and bolt, the direct drive motor coupling, the drive belt, the transmission, the drive motor, the timer, the lid switch, the selector switch and the water level switch. To verify if the electrical parts are causing the issue you need to use a multimeter to check the continuity of each part. I hope this helps. Thank you and have a great day!

9 people found this helpful.

Was this helpful?

Thank you for voting!

Shannon

August 25, 2017

Washer makes a high pitch noise while draining water. It spins and dries clothes just fine. The noise is sporadic. Some times it will do it when spinning. Not sure if it's the mortor coupler or the clutch assembly.

For model number LSR7233BW0

Hi Shannon,

Thank you for your question. For a problem like that it sounds as though one of those two parts has either debris causing the noise or they have worn down a bit. I think you should check your clutch assembly first, and then also do a physical check on your coupler as well. Without looking at your appliance myself, I could not say which one it would be exactly because it could be either. Good luck with your repair.

9 people found this helpful.

Was this helpful?

Thank you for voting!

David

December 9, 2017

Hi, my washing machine does not agitate. It spins fine and everything seems to work fine. I replaced the agitator repair kit and checked the direct drive motor coupling, but there is no visible damage. Could it be that is just worn out or what other parts might be faulty?

For model number WTW5200VQ2

Hello David,

Thanks for your question. We would advise checking the drive block as well for any signs of damage and replacing it if it is not intact.

I hope this helps.

7 people found this helpful.

Was this helpful?

Thank you for voting!

Related Parts:

Jason

August 9, 2017

Will this part fix....start a wash cycle, it fills up and agitates for a decent time but then starts spinning but not draining, it's pumping the water back up top into the washer and will continue to do so until you stop the machine

For model number GSX9885JQ0

Hello Jason,

Thank you for the question. Sounds like you need to replace the Direct Drive Water Pump. This direct drive water pump, also known as washing machine drain pump. If this part is defective it will not pump the water out of the appliance.

Good luck with this repair!

6 people found this helpful.

Was this helpful?

Thank you for voting!

Related Parts:

- < Prev

- 1

- 2

- 3

- Next >

✖

Ask a Question

Ask our experts a question on this part and we'll respond as soon as we can.

Sorry, we couldn't find a match for "".

Here's a guide for finding your model number.

Something went wrong. Please try again later.

Your Question Has Been Submitted!

Our experts will send you an email as soon as your question has been answered.

Related Parts

Model Cross Reference

This part works with the following models:

PartSelect Number: PS1485646

Manufacturer Part Number: 285753A

Manufacturer Part Number: 285753A

Brand

Model Number

Description

Kenmore

10682872600

Washer

- Kenmore Washing Machine Model 106.82872600 (10682872600, 106 82872600) Parts

Kenmore

1101050299

Washer

- Kenmore Washing Machine Model 110.1050299 (1101050299, 110 1050299) Parts